Negotiable

The date of payment from buyers deliver within days

Jiangsu

Long-term effective

2017-12-17 20:20

190

Company Profile

Company Profile

By certification [File Integrity]

Contact:Ms. Elaine Gu(Mr.)

Email:

Telephone:

Phone:

Area:Jiangsu

Address:Jiangsu

Website: http://czhuamei.better-elec.com/

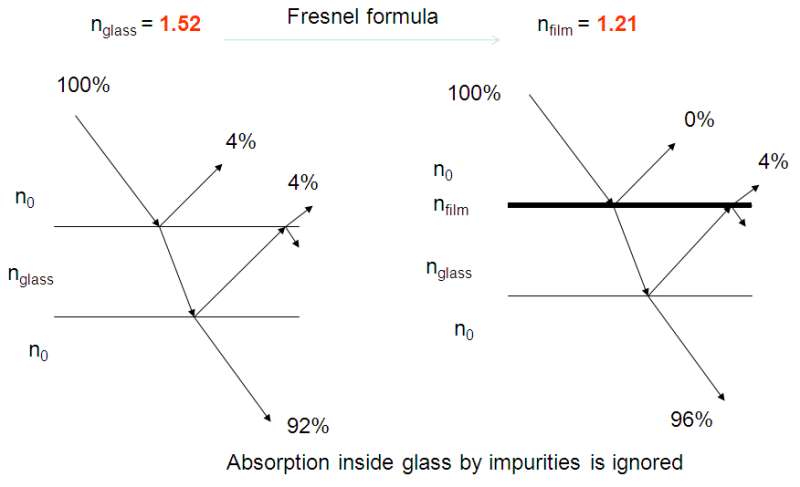

3.2mm Solar Panel Use Tempered Ar-Coating Ultra Clear Solar Glass, combined with nanometer anti-reflective coating technology,increase solar transmittance by way of decreasing light reflectance and improve the solar cell phtotelectric conversion efficiency.Meanwhile,it reduces the reflected glare of the glass and the pollution caused by the reflectance to the environment. The hydrophobic behavior of the AR coating could in some degree protect the dust and dirt from shading the light and improve the cleaning performance of the glass. With the outstanding characteristics of the high solar lights transmittance, the low reflectance, the low iron, the high mechanical strenght and the high flatness, it is one of the indispensable important parts of solar cell and has been widely used to photovoltaic power generation all over the world.

| Products | 3.2mm Solar Panel Use Tempered Ar-Coating Ultra Clear Solar Glass |

| Thickness | 3.2mm |

| Size | Can be customized,maximum size:1200*2200mm |

| Solar transmittance | 3.2mm>93.5%,with AR coating |

| Applications | For solar cell module |

| Payment terms | T/T |

| Delivery | Within 15 days after receiving the deposit |

| MOQ | 500 sqm |

| Port | Shanghai |

| Test | Standards | Test method | Results | |

| 1 | Appearance | EN1096-2 | Surface is clean, no scratches,spots or pinhole | Qualified |

| 2 | Light transmittance | ISO 9050 | The ratio after coating is higher than before >2.5 | >2.6 |

| 3 | Adhesion | ASTMD3359 | The cutting edge is very smooth , no grid slide, | 0 level |

| 4 | Pencil hardness | ASTMD3363 | No thickness of film which scratched by pencil more than 3mm | ≥6H |

| 5 | Salt spray test | EN1096-2 | With 5%(±1)NaC1,under 35ºC,last 4-9days,record the data before and after the test, T<1.0 |

4 days, T=0.57 9 days, T=0.91 |

| 6 | Thermal Cycle | IEC61215/10 | Keep the temperature between -40ºC and 85ºC,±2ºC,200 times,(around 1000 hours),record the data before and after the test,T<1.0 | T=0.48 |

| 7 | Damp Heat Test | IEC61215/10 | Under 85ºC,±2ºC,relative humidity is 85ºC,±5ºC,around 1000 hours,record the data before and after the test,T<1.0 | T=0.63 |

| 8 | Wet-cold test | IEC61215/10 | Humidity is 85,±5ºC,temperature is 85ºC,±2ºC,fall to -40ºC,cycle for 10 times.Record the data before and after the test,T<1.0 | T=0.80 |

| 9 | Outdoor exposure | IEC61215/10 | Test with the moniter in outdoor temperature,total radiation need to be 60kmh·m-2 .Record the data before and after the test,T<1.0 | T=0.59 |

| 10 | Mechanical Loading | IEC61215/10 | Adding the load to 2400Pa and make it distributed.Keep 2-3 times;the layer wasn't broken and no serious defects in appearance | Qualified |